IoT Analytics released a new analysis, based on the ’Industrial IoT & Industry 4.0 Case Study Report 2023’.

Key insights:

- Digitalization has become essential for industrial companies worldwide, as IoT Analytics expects the industrial IoT market to reach $145 billion in 2023.

- The Industrial IoT and Industry 4.0 Case Studies Report 2023 delves into 22 case studies, exploring their project objectives, technologies deployed, lessons learned, challenges, and outcomes.

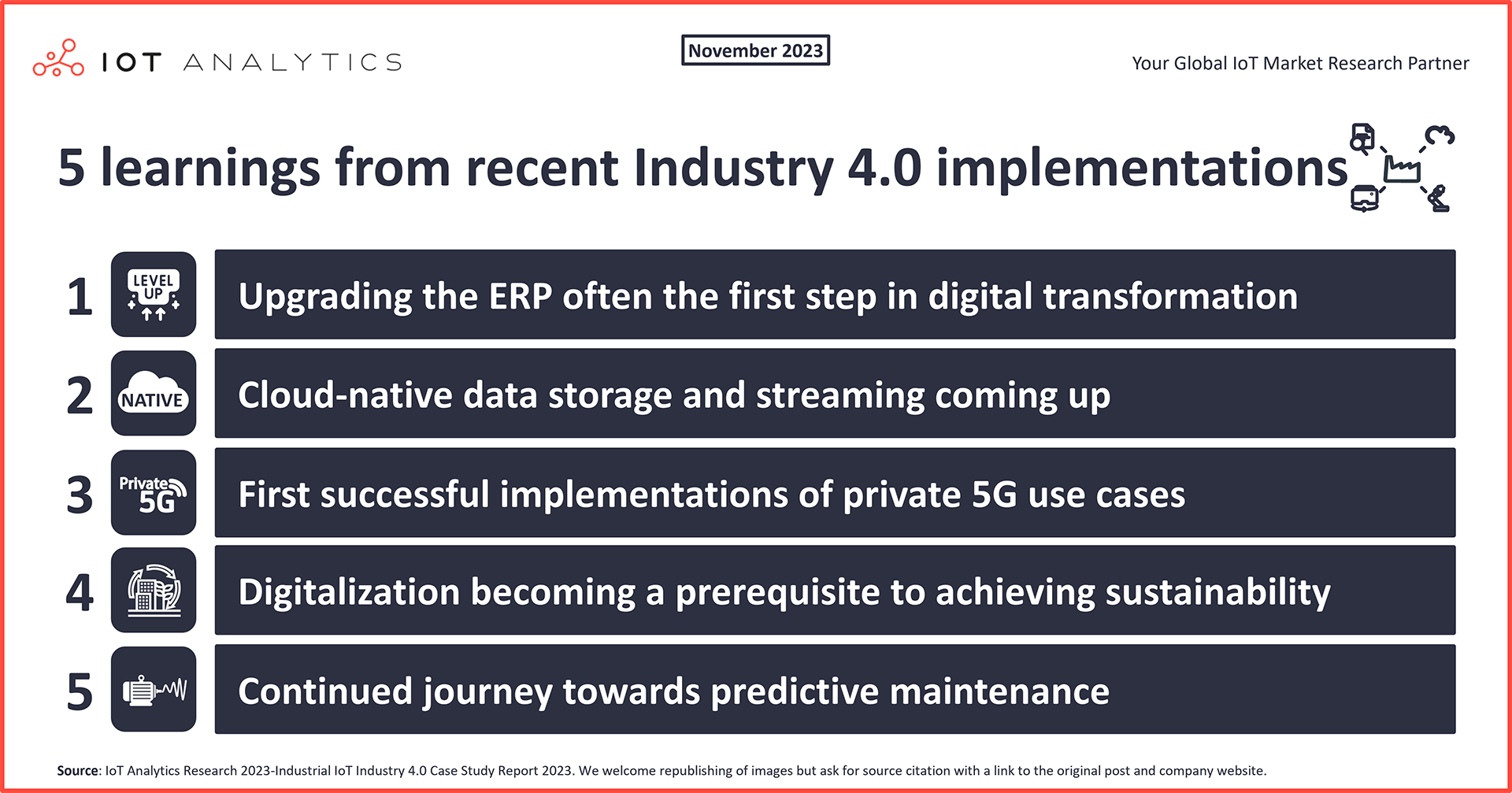

- In this article, we share five learnings from the report: 1) Upgrading the ERP is often the first step in digital transformation, 2) cloud-native data storage and streaming are coming up, 3) first successful implementations of private 5G use cases, 4) digitalization becoming a prerequisite to achieving sustainability, and 5) the continued journey toward predictive maintenance.

Key quotes:

Rajini Nair, Analyst at IoT Analytics, remarks: “Upon analyzing the case studies outlined in the report, it becomes evident that digitalization is a key catalyst driving technological progress in industrial settings. This includes the enhancement of ERP systems and the migration of data to cloud platforms equipped with real-time streaming capabilities. Furthermore, digitalization proves essential in harmonizing companies with their sustainability objectives. Strategies such as the implementation of predictive maintenance algorithms and the adoption of private industrial 5G use cases are leveraged to improve operational efficiency. Looking forward, the technological landscape is transforming with the rise of AI, poised to shape the future of manufacturing.”

Digitalization has become crucial to manufacturers globally

Digitalization has become crucial for manufacturers in their respective competitive landscapes. IoT Analytics estimates the industrial IoT market to reach $145B in 2023, with a CAGR of 17.9% until 2030, as more and more companies undertake digital transformation initiatives.

For many, digitalization has already become a game changer:

- Carmaker Mercedes has achieved 25% greater efficiency in its S-class assembly after optimizing the value chain and introducing innovative technologies at its Germany-based Factory 56 facility.

- Energy giant TotalEnergies aims to generate $1.5 billion annually in savings with its digital solutions by 2025.

- Chemical company Covestro increased efficiency and reduced unnecessary downtime by shifting from calendar-based to condition-based maintenance.

These are just some of the benefits of the digital transformation initiatives our research uncovered as part of the 255-page Industrial IoT and Industry 4.0 Case Studies Report 2023. The report delves into 22 recent industrial digital transformation case studies, looking at initiatives related to digital transformation, data architecture, predictive maintenance, AI, and industrial 5G.

Benefits of case studies for digitalization journeys

Case studies by peers or companies in other industries are a great way to learn about digitalization, identify common challenges, develop a view of best practices, and understand how companies manage to scale.

The 22 case studies in our report offer readers a diverse set of manufacturing examples of current IIoT and Industry 4.0 projects, along with project objectives and takeaways from each. Our analysis of these takeaways yielded many trends in these companies’ digital transformation journeys, five of which we will delve into in this article (including selected highlights from the report):

-

1. ERP: An upgraded ERP is often the first step to digital transformation.

2. Cloud: Cloud-native data storage and streaming are increasingly accepted.

3. 5G: First manufacturers have successfully implemented private 5G use cases.

4. Sustainability: Digitalization is becoming a prerequisite to achieving sustainability objectives.

5. Maintenance: The journey toward predictive maintenance and remote monitoring continues.

Learning 1: An upgraded ERP is often the first step to digital transformation

Our analysis found that many manufacturers elect to prioritize upgrading their ERP systems to ensure their various data sources are connected before prioritizing other digital transformation initiatives. Since ERP systems are often the central nervous system of a business, prioritizing an updated ERP allows different departments to share and operate on the same data, reducing errors and improving efficiency.

Selected highlight: Celanese

In recent years, US-based chemical manufacturer Celanese has acquired several businesses or divisions from other companies. Celanese had been operating on a legacy SAP ERP system, and the acquired assets had different legacy ERP environments, making cross-section integration difficult. Celanese’s global CIO, Sameer Purao, did not want the company to invest in integrating the new acquisitions into older technology. Given this situation and Celanese’s adoption of a strategic, long-term approach to a scalable digital transformation plan, an ERP upgrade became necessary.

“Our previous ERP system had been a backbone, but it was close to 20 years old. Given its age, we didn’t want to invest in transforming until we upgraded that piece first. The acquisitions underscored that it wouldn’t make sense to invest in integrating them into older technology, so we opted to upgrade.” – Sameer Purao, senior vice president and global CIO, Celanese Corporation

In May 2023, Celanese announced that it had completed its upgrade to SAP S/4HANA. Further, since Celanese acquired DuPont’s Mobility & Materials (M&M) business just six months prior, it quickly cutover to upgrading M&M’s legacy ERP system as well, which is expected to be completed in the first half of 2024.

While there are other major aspects of Celanese’s digital transformation journey detailed in our report, this upgrade to its ERP provided a stronger backbone from which other digitalization solutions could be built. Another benefit of this upgrade is improved visibility and collaboration, enhancing transparency and teamwork and allowing for efficient data access across the enterprise.

Learning 2: Cloud-native data storage and streaming are increasingly accepted

The cloud market nearly doubled between 2020 and 2022, growing from $109 billion to $206 billion, based on our analysis of global cloud projects. While the COVID-19 pandemic certainly played a major role, it was not the only growth factor. Our analysis found that large-scale enterprise digitalization efforts and strong SaaS adoption also helped fuel this growth.

Cloud storage and data streaming allow companies to centralize and share their data with a smaller footprint than running their own on-premises servers, which comes with footprint and maintenance costs. Moving these services to the cloud also allows companies to scale without the need for significant capital investment in physical hardware.

Selected highlight: Michelin

In 2019, tire manufacturer Michelin started using Apache’s Kafka event streaming platform on-premises in its data centers to gain real-time insights and process data as continuous streams. However, as its operational footprint expanded, so did the resources it had to dedicate to maintaining the solution. By Q4 2019, Michelin’s IT department initiated its migration to the cloud, with Microsoft Azure as the cloud partner.

“One of the challenges with [streaming technology] Kafka was its operational complexity, especially as the footprint expanded across our organization. It’s a complex, distributed system, so we had to allocate a lot of our valuable technical resources and expertise to babysit it and keep it running.” – – Olivier Jauze, now CTO of Experiences Business Line, Michelin

By 2021, Michelin migrated its services to Confluent Cloud for Azure, a Kafka-based platform, to support its multi-cloud environment. Soon after, the company began exploring use case projects and has since migrated one of its most critical projects, online order management, to the cloud—replacing its on-premises orchestrator. By 2023, Michelin expanded its cloud-based event streaming architecture into several departments, including supply chain management, customer services, manufacturing, and R&D.

Through its adoption of cloud-native data storage and streaming, Michelin achieved the following benefits (among other things):

- Cost savings: Estimated 35% in cost savings in the cloud compared to on-premises operations

- Improved uptime: 99.99% uptime

Learning 3: First manufacturers have successfully implemented private 5G use cases

As 5G continues its public rollout globally, some manufacturers have successfully deployed private 5G networks to enable new use cases within their facilities. While faster speeds and lower latency may seem like key adoption drivers, our analysis found that improved reliability over Wi-Fi, enhanced cybersecurity, and the ability to access data locally are the core motivating factors.

Our analysis also found that during the public rollout of 5G, some companies did not simply dive into integrating 5G-specific technology. Instead, many integrated robust LTE solutions that were upgradable to 5G with relative ease (or so-called 4.9G solutions) once the technology evolved or became approved for industrial use.

Selected highlight: Airbus

To increase aircraft production and validation efficiency, European multinational aerospace corporation Airbus partnered with Ericsson, a Swedish multinational telecommunications company, in 2021 to implement private industrial 5G networks at 11 aircraft assembly manufacturing sites in Europe. The approach began with implementing 4G networks that either already had 5G capabilities or could seamlessly upgrade to 5G.

However, Airbus is not limiting this deployment to its European facilities. During a Q&A at the 5G Manufacturing Forum in November 2022, Hakim Achouri, the 5G and IoT solutions expert for digital aviation at Airbus, noted, “Airbus is going way beyond 11 networks at 11 sites, expanding beyond its core European manufacturing bases in France and Germany, to also deploy private 5G in Canada, China, Spain, the UK, and the US.”

With its implementation of private 5G networks at its production and assembly facilities, Airbus has realized the following benefits:

- Ability to implement advanced use cases: This includes site surveillance, efficient flight-to-ground data offloads, quality inspections, and the operation of automated guided vehicles (AGVs).

- Enhanced user experience: With increased speed, bandwidth, and reliability, employees at the production sites have access to more data, making operations smoother, more efficient, and more secure.

- Scalability through reusability: By developing a pattern in its strategy, Airbus was able to roll out private 4G/5G networks across its many sites with consistent quality and performance.

Learning 4: Digitalization is becoming a prerequisite to achieving sustainability objectives

We recently noted a trend of companies deploying digital twins to help realize their sustainability goals. But it is not simply digital twins assisting companies on this front—digitalization projects overall are helping companies monitor energy consumption, optimize resource usage, and reduce their environmental footprint in the manufacturing process.

Backing this awareness and trend toward sustainability are data points from our latest What CEOs Talked About report, where “sustainability” and related terms remained among the most discussed topics in boardrooms.

Selected highlight: TotalEnergies

French multinational energy and petroleum company TotalEnergies has publicly declared its ambition to achieve carbon neutrality by 2050. To meet this goal, the energy company has leveraged digital solutions to advance the implementation of sustainability measures on its offshore platforms.

For instance, TotalEnergies retrofitted their pipes with LoRaWAN-connected temperature sensors to detect gas leaks along their flare networks. As hydrocarbons are released, the temperature of the pipes significantly changes. When this change is detected, operators are alerted via emails for immediate action. This not only helps limit the release of hydrocarbons but also saves TotalEnergies money by reducing the loss of product.

Learning 5: The journey toward predictive maintenance and remote monitoring continues

According to our Predictive Maintenance and Asset Performance Market Report 2023–2028 (published in November 2023), the predictive maintenance market reached $5.5 billion in 2022. While the report notes several tailwinds supporting this interest and market growth, such as skill shortages and interest in reducing energy usage and CO2 emissions, costs are a major driver, as noted in our case studies report as well.

Equipment failure, especially during core operational hours, reduces productivity and adds repair expenses. To avoid these costs, companies often use preventative maintenance procedures, such as time-based inspections and repairs or condition criteria from sensors or physical measurements to trigger preventative intervention. However, intervening based on time can be inefficient since the equipment may not be in need of repair at that time, and data collection/monitoring requires personnel to conduct these tasks.

By implementing digital solutions, companies can remotely monitor the condition of critical equipment and establish conditions in which intervention is actually needed well before failure occurs.

Selected highlight: Battalion Oil Corp

US-based Battalion Oil Corp partnered with Novity, a US-based predictive maintenance solutions company, to pilot a predictive maintenance solution to detect valve leaks within their compressors and reduce unexpected compressor downtime. Initially, Battalion would sporadically measure valve cap temperatures using handheld devices to identify potential gradual leaks that could lead to a failure. While the checks were intended to be conducted daily, varying daily maintenance tasks and priorities often disrupted these important checks.

“Predictive automation is a game-changer for the oil and gas industry. By analyzing data in real-time and making accurate predictions about future events, drilling companies can optimize their operations to maximize efficiency, reduce costs, and improve safety. This technology has the potential to transform the way we do business and stay competitive in today’s market.” – John Smith, CEO of Oil and Gas Exploration Company

An initial step in the solution was to use a crank angle sensor and pressure transducers. However, physical crank angle sensors are usually the most difficult and expensive sensors to install, so the engineers developed a virtual crank angle sensor based on physics-based and data-driven methods using data from the pressure sensors.

After validating that the rotational position calculated by the virtual sensors matched the position provided by the physical sensors, engineers applied prognostic methods to the data from the virtual crank angle sensor and physical pressure sensors. The result was predicted gradual valve failures several weeks in advance—five to seven days on average before temperature checks indicated a gradual leak.

The digital transformation journey carries on

The Industrial IoT and Industry 4.0 Case Studies Report 2023 delves further into the above-mentioned and 18 other case studies of ongoing digital transformation projections. While these companies and many others are advancing in their digital transformation journeys, there is still a long road ahead for many companies, some of which still rely on analog, pen-and-paper methods in their facilities. Even still, many companies are already experiencing real value, e.g., Mercedes’ achieving 25% greater efficiency and Battalion observing signs of gradual valve failures several weeks in advance.

Digitalization has become more than a nice-to-have for manufacturers today—it has become crucial for them in their respective competitive landscapes. The market reflects this assessment: according to our enterprise IoT market dashboard, the IIoT market size in 2023 is approximately $145 billion, with a forecasted CAGR of 17.9% between 2023 and 2030.

Looking ahead, AI continues to become a major theme in companies’ digital transformation initiatives. According to our continual series What CEOs Talked About, the topic and its related terms have already been of high and growing interest in boardrooms throughout 2023. We see a plethora of generative AI projects across the board, even in the industrial space (which we will report on soon). We will continue to monitor this space and highlight interesting case studies from adopters.